The food tech startup Freight Farms is giving new life to old shipping containers, and at the same time giving impetus to locally grown food.

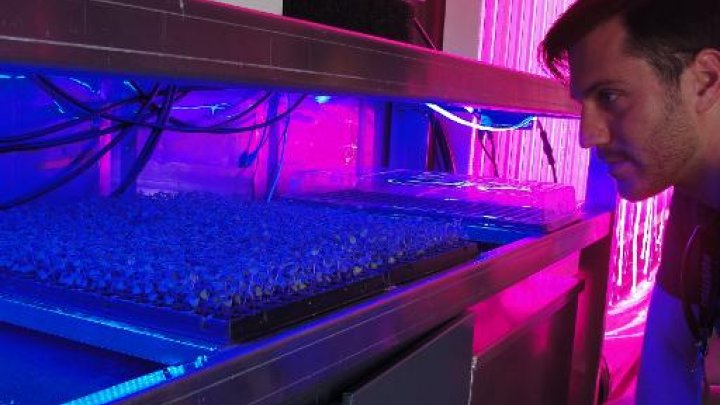

At the Collision technology conference in Las Vegas, the company showed off its basil sprouts nurtured in a used cargo container equipped to let crops flourish just about anywhere.

“Our mission is to create a more connected and sustainable food system,” Caroline Katsiroubas of Freight Farms told AFP at the event.

“Everyone wants to be more local, know where their food comes from and have a relationship with people growing their food.”

Jon Friedman and Brad McNamara founded the Boston-based startup in 2010 with a vision of outfitting used shipping containers with sophisticated hydroponics equipment to turn them into boxed farms that could be placed in alleys, abandoned lots, parking lots or any other location where agriculture would typically be out of the question.

There is a massive supply of old insulated containers once used to ship refrigerated goods around the world on cargo ships, according to Katsiroubas. Evidently, it is cheaper to buy new containers than to repair old units.

“These containers all had past lives,” she said with a gesture. “We clean them up and retrofit them.”

Freight Farms installs equipment that controls environmental factors ranging from temperature and carbon dioxide levels to air flow and nutrients in water fed to crops.

– Tilling recycled soda bottles –

Seeds in “grow trays” sprout under blue light ideally suited for young plants. They are transferred to take root in an artificial soil of sorts made of recycled plastic soda bottles in “zip grow towers” that stand upright. The effect is like plants growing along the sides of columns.

Flexible strings of lights hanging from the container ceiling simulate the necessary sunshine.

All the nutrients needed by plants are in water fed through the pseudo-soil. Each container produces as much crop as about 1.8 acres (0.7 hectares) of traditional farmland, and uses about 90 percent less water in the process, according to Katsiroubas.

There is even an application that lets container farms be completely monitored and controlled from afar.

Each container uses about 30,000 kilowatt hours of electricity a year, roughly the equivalent of that used by two US households, but less than a greenhouse producing the same amount of crop.

Going solar for electricity is not yet an option, since it would take more solar cells than could fit atop a container, according to Katsiroubas.

Freight Farms modifies equipment to be more energy efficient and hopes that, along with advances in solar cell efficiency, containers will one day be self-sufficient when it comes to power.

“The electricity we are pulling is definitely a pain point,” Katsiroubas said. “It would be great if we were completely off the grid, but at the moment we have to be plugged in.”

Freight Farms reasons that crop-growing energy use is offset to some degree by decreases in resources devoted to transporting produce long distances and less spoilage.

Crops can be ready for harvest in six to eight weeks depending on what is being grown, and restaurants have taken to paying premium prices for high-quality produce that is locally sourced, according to Freight Farms.

Urban farmers can even find out what is in demand at restaurants or markets and pick those crops to plant, since climate, weather and soil are not concerns.

“We have these wild visions of cities being self-sustaining and every school operating one,” Katsiroubas said.

“We are absolutely not trying to take out traditional farming.”

Freight Farms systems have a starting price of $76,000, and about three dozen have been sold in North America, according to Katsiroubas.